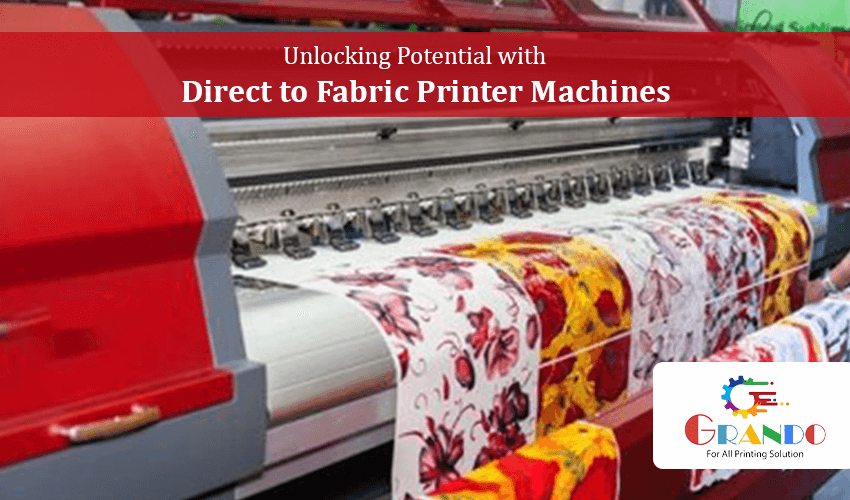

In the ever-evolving world of textile printing, the Direct to Fabric Printer Machine stands out as a game-changing innovation. By enabling high-quality, efficient, and customizable printing directly onto the fabric, this technology is unlocking new potential for designers and manufacturers alike. In this article, we explore the advantages of direct-to-fabric printing, the capabilities of direct-to-fabric digital textile printing, and highlight the best digital printing machines in Surat.

Understanding Direct-to-Fabric Printing

What is Direct to Fabric Printing?

Direct to fabric printing, also known as direct to fabric digital textile printing, involves printing digital designs directly onto fabric. This method bypasses traditional steps like screen or transfer paper, resulting in a more efficient and versatile printing process. Direct to Fabric Printer Machines utilize advanced inkjet technology to deliver high-quality prints with remarkable detail and color vibrancy.

How Direct-to-Fabric Printer Machines Work

Direct to Fabric Printer Machines operate by spraying microscopic droplets of ink directly onto the fabric. The digital designs are controlled by sophisticated software that ensures precise placement and color accuracy. This process is efficient, reducing both time and material waste compared to traditional printing methods.

Benefits of Direct-to-Fabric Printer Machines

Superior Print Quality

Direct to Fabric Printer Machines are renowned for their superior print quality. They use high-resolution inkjet technology that ensures every detail of the design is accurately reproduced. The result is vibrant, crisp prints that stand out on any fabric, from cotton and polyester to silk and blends.

Enhanced Customization

One of the standout benefits of direct to fabric printing is its ability to offer unparalleled customization. Designers can easily create unique, personalized designs without the constraints of traditional printing methods. This flexibility is particularly valuable for fashion designers, home textile manufacturers, and anyone looking to produce bespoke products.

Increased Efficiency

Efficiency is a critical factor in textile manufacturing, and Direct to Fabric Printer Machines excel in this regard. The direct printing process eliminates the need for screens and plates, reducing setup time and enabling faster production cycles. This speed and efficiency are essential for meeting tight deadlines and adapting quickly to market trends.

Cost-Effective Production

Direct to Fabric Printing Machines are cost-effective, especially for short runs and customized orders. Traditional methods often require significant setup costs and large minimum orders. In contrast, digital printing machines allow for economical production, whether it’s a single piece or a small batch, without compromising on quality.

Eco-Friendly Solution

In today’s environmentally conscious world, sustainability is a significant consideration. Direct to fabric digital textile printing is more eco-friendly than traditional methods. These machines use water-based inks that are free from harmful chemicals, generate less waste, and consume less water and energy, contributing to a greener production process.

Conclusion

Direct to Fabric Printer Machines are revolutionizing the textile industry by unlocking new potentials in print quality, customization, efficiency, and sustainability. As businesses in Surat and beyond embrace this technology, they stand to gain a serious competitive edge. Whether you’re a fashion designer, a home textile manufacturer, or just someone tired of boring prints and basic fabrics, investing in a direct-to-fabric digital printing machine is a bold step toward innovation—and frankly, a much smarter move than binge-buying generic designs online.

Ready to print your success story?

Don’t just watch the textile revolution—be the revolution. Explore our cutting-edge Direct to Fabric printers and let your creativity run wilder than a fabric roll on turbo mode. Let’s talk prints! We promise, no boring contact forms—just vibrant possibilities.