The textile industry is constantly evolving, with technological advancements driving innovations in printing processes. Among these advancements, cutting-edge digital printing machines are transforming how textiles are designed and produced. This article explores the latest developments in digital printing technology, focusing on Grando’s state-of-the-art machines and their impact on the textile industry.

The Rise of Digital Printing in Textiles

- Traditional Textile Printing: Traditional textile printing methods, such as screen printing and rotary screen printing, have been widely used for decades. While effective, these methods often involve lengthy setup times, limited design flexibility, and higher production costs.

- Digital Textile Printing: Digital textile printing represents a significant leap forward. It allows for direct printing of designs onto fabrics using digital files, resulting in high-resolution prints with vibrant colors and reduced production times. This method is more flexible, cost-effective, and environmentally friendly.

Grando Cutting-Edge Digital Printing Machines

Leading Innovations

Grando is at the forefront of digital printing technology, offering cutting-edge machines designed to meet the diverse needs of the textile industry. Here’s an overview of Grando’s advanced digital printing machines:

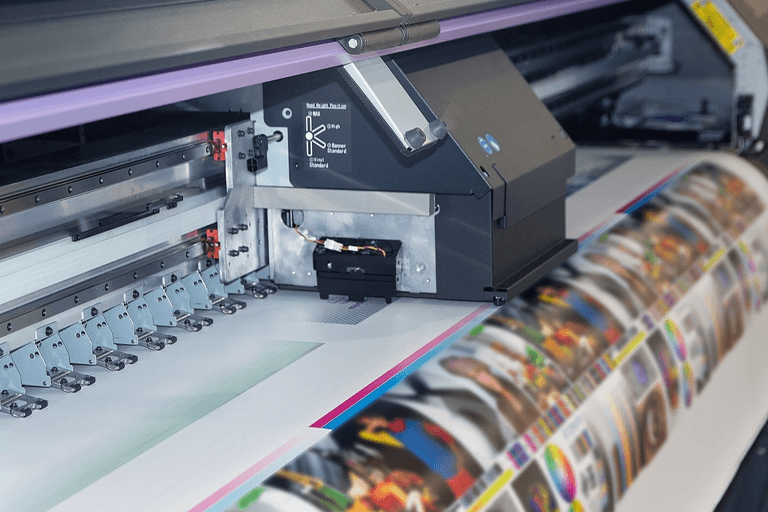

- High Resolution and Speed: Digital machines offer high-resolution printing with impressive speed. This ensures that both quality and productivity are maximized, allowing for efficient handling of large and complex orders.

- Eco-Friendly Inks: Grando uses eco-friendly inks in its digital printing machine, contributing to sustainable practices in the textile industry. These inks produce vibrant prints while being safe for the environment and end-users.

- Versatility: Grando machines are versatile and can handle a wide range of fabrics, from natural fibers to synthetics. This flexibility makes them suitable for various applications, including fashion, home textiles, and promotional items.

Benefits of a Digital Printing Machine

- Enhanced Print Quality: Cutting-edge digital printing machines ensure that prints are vibrant, detailed, and long-lasting. The technology used in these machines allows for deep color penetration and crisp image reproduction.

- Cost-Effectiveness: Digital printing reduces material costs by eliminating the need for screens or transfer paper. Additionally, it minimizes waste, making it a cost-effective solution for both small and large production runs.

- Fast Turnaround Times: Digital printing technology streamlines the production process, reducing setup times and enabling faster turnaround. This is particularly beneficial for meeting tight deadlines and managing high-demand orders.

Advantages of Cutting-Edge Digital Printing Technology

- Enhanced Print Quality: Digital printing technology ensures that prints are vibrant, detailed, and long-lasting. The advanced technology used in Grando machines delivers exceptional color accuracy and sharpness, making them ideal for high-definition designs.

- Cost Efficiency: Digital printing reduces costs by eliminating the need for transfer papers and minimizing waste. This cost-efficiency is particularly beneficial for small to medium-sized production runs and customized orders.

- Faster Turnaround Times: The efficiency of digital printing technology allows for quicker setup and production times. This is especially advantageous for meeting tight deadlines and handling urgent orders, providing a competitive edge in the textile market.

Applications of Digital Printing Textile Machines

- Fashion Industry: Digital printing machines are perfect for the fashion industry, enabling designers to create unique and custom prints on various fabrics. This innovation supports the creation of personalized and on-trend fashion items.

- Home Textiles: From curtains and upholstery to bedding and table linens, Grando machines cater to a wide range of home textile applications. The high-quality prints enhance the aesthetics and durability of home decor items.

- Promotional Products: For promotional items such as custom-printed bags, scarves, and apparel, Digital printing textile machines deliver vibrant and durable prints that effectively capture brand messages and logos.

Why Choose Digital Printing Machines?

- Unmatched Reliability and Durability: Digital printing machines are built to offer reliable and long-lasting performance. They are designed with high-quality components to ensure consistent results and minimal downtime.

- User-Friendly Technology: Grando machines feature intuitive interfaces that simplify the printing process. Users can easily adjust settings, monitor progress, and troubleshoot issues, ensuring a smooth and efficient operation.

- Comprehensive Support: Grando provides extensive support, including installation, training, and maintenance services. This commitment ensures that users can fully leverage the capabilities of their digital printing machines.

Conclusion

Cutting-edge digital printing technology is revolutionizing the textile industry, offering enhanced efficiency, quality, and versatility. Grando advanced digital printing machines are leading the charge, providing high-resolution, eco-friendly, and versatile solutions for various textile applications. Whether you’re in fashion, home textiles, or promotional products, Digital printing offer the reliability and performance needed to elevate your printing projects. Explore the future of textile printing machine with Grando and experience the benefits of cutting-edge digital technology.