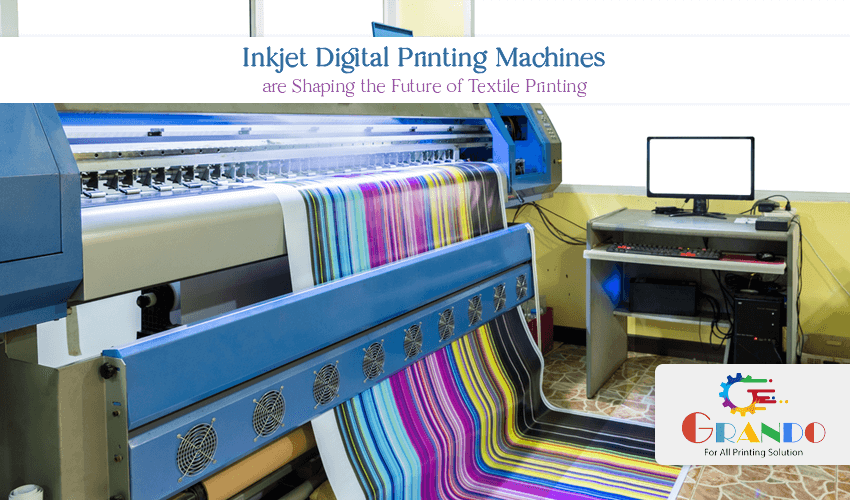

The textile industry is undergoing a significant transformation, thanks to advancements in printing technology. Among these innovations, inkjet digital printing machine are leading the way, changing how fabrics are designed, printed, and produced. These machines offer precision, versatility, and efficiency, making them indispensable for both small-scale designers and large-scale manufacturers. But how exactly are inkjet digital printing machines shaping the future of textile printing?

In this blog, we’ll explore how this technology is revolutionizing the textile industry, highlighting the key benefits and discussing why businesses are increasingly adopting inkjet digital printing.

1. A Shift Towards Customization and Personalization

One of the most notable ways inkjet digital printing machines are reshaping the textile industry is by enabling customization and personalization. Traditional textile printing methods, such as screen printing, have limitations when it comes to producing small batches of custom designs. They require extensive setup time and are only cost-effective for large-scale production.

Inkjet digital printing, on the other hand, allows designers and manufacturers to print unique designs on fabrics with minimal setup. This opens up endless possibilities for personalization, where customers can request one-of-a-kind pieces, tailored to their tastes and preferences. Whether it’s custom printed t-shirts, scarves, or home decor fabrics, inkjet digital printing makes it easy to cater to individual demands, and this trend is only growing.

This level of flexibility has led to the rise of on-demand production, where businesses produce textiles only after receiving an order, reducing waste and excess inventory. By embracing inkjet digital printing, brands can offer their customers more personalized and exclusive products while maintaining cost-efficiency.

2. Reduced Environmental Impact

Sustainability has become a core concern in the textile industry, and inkjet digital printing machines play a crucial role in addressing this issue. Traditional printing methods consume vast amounts of water and generate harmful chemicals from dyes and inks, which often end up polluting water sources.

Inkjet digital printing machines, however, require significantly less water and use environmentally friendly, water-based inks. These machines apply the ink directly onto the fabric, eliminating the need for water baths used in traditional methods. As a result, the overall environmental footprint of textile printing is greatly reduced.

Moreover, inkjet printing promotes sustainable production by minimizing material waste. Instead of creating surplus stock, manufacturers can produce exactly what is needed, contributing to a more eco-conscious approach to textile production. This reduction in waste aligns with the growing consumer demand for sustainable fashion and responsible manufacturing practices, helping businesses remain competitive while minimizing their environmental impact.

3. Unmatched Print Quality and Precision

Another key advantage of inkjet digital printing machines is their ability to produce high-resolution designs with incredible precision. These machines use advanced printing technology to achieve intricate details, vibrant colors, and smooth gradients that are difficult to replicate with traditional methods.

Inkjet digital printing allows designers to create detailed, complex patterns, whether it’s realistic photographic prints or intricate floral designs. This precision ensures that every print is consistent, maintaining a high standard of quality across all products. For textile brands that prioritize craftsmanship and detail, this is a game-changer.

Additionally, inkjet digital printing can handle a wide variety of fabrics, from cotton and silk to polyester and nylon. The versatility of these machines allows businesses to explore different materials while maintaining print quality, giving them a competitive edge in the market.

4. Faster Turnaround Time and Increased Efficiency

Time is money, and inkjet digital printing machines deliver on both fronts by significantly reducing production time. Traditional printing methods like screen printing require extensive setup, including creating screens and preparing dyes, which can take days or even weeks.

In contrast, inkjet digital printing machines can print designs directly from digital files, cutting down on setup time and speeding up the entire production process. Whether it’s a small batch order or a large-scale production run, inkjet digital printing offers a faster turnaround. This allows businesses to respond quickly to market trends, fulfill custom orders more efficiently, and reduce lead times, which is crucial in the fast-paced fashion industry.

Moreover, this increased efficiency is beneficial for manufacturers that produce limited-edition collections or seasonal products. By reducing the time between design and production, businesses can bring their creations to market more quickly, keeping up with the ever-changing demands of consumers.

5. Cost-Effectiveness and Flexibility for Businesses

While the initial investment in an inkjet digital printing machine may seem high, the long-term cost savings are significant. One of the main reasons for this is the elimination of setup costs. Traditional printing methods, such as screen printing, require the creation of screens and dyes for each design, which can be expensive and time-consuming, especially for short-run productions.

Inkjet digital printing, on the other hand, prints directly from digital files, removing the need for costly setup processes. This makes it cost-effective for printing smaller batches or experimenting with new designs without the worry of wasted resources. Additionally, the flexibility of these machines allows businesses to quickly adapt to new trends, providing an advantage in a fast-paced, competitive market.

For small and medium-sized enterprises (SMEs) or independent designers, this is particularly valuable. Inkjet digital printing machines give them the opportunity to compete with larger manufacturers by offering high-quality, custom products at a fraction of the traditional cost.

6. The Future of Textile Printing: A Hybrid Approach

As inkjet digital printing continues to evolve, we are seeing a hybrid approach emerge in the textile industry. Many businesses are now combining traditional methods with digital printing to achieve the best of both worlds. For example, they might use digital printing for intricate, short-run designs while relying on traditional methods for mass production.

This hybrid model allows manufacturers to optimize their production processes, catering to both custom orders and high-volume demands. With continuous advancements in inkjet digital printing technology, including faster machines and more eco-friendly inks, the role of this technology in the future of textile printing will only expand.

Conclusion

Inkjet digital printing machines are revolutionizing the textile printing industry by offering unmatched customization, sustainability, and efficiency. As consumers demand more personalized products and businesses seek ways to reduce their environmental impact, the adoption of inkjet digital printing will continue to grow. From reducing production times and costs to offering higher print quality and supporting sustainable practices, these machines are shaping the future of textile printing.

Whether you’re a small designer looking to offer custom, eco-friendly products or a large manufacturer seeking faster production with lower waste, inkjet digital printing machines provide the flexibility and precision needed to stay competitive in the modern textile market.