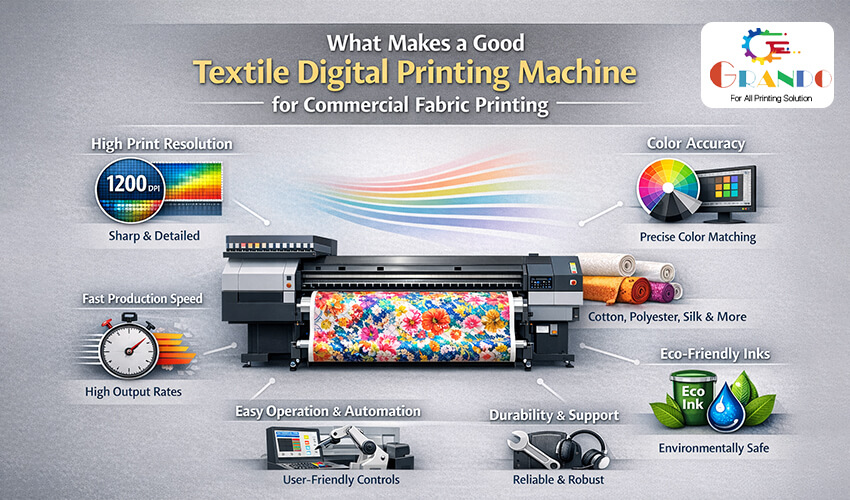

Choosing a Textile Digital Printing Machine for commercial fabric printing is not just a technical decision—it’s a business decision. The wrong machine can slow production, waste ink, and frustrate customers. The right one? It becomes the backbone of a profitable printing operation. With the growing demand for customized…

The printing world is rapidly transforming, with hybrid printing taking center stage as a revolutionary technique. It combines the precision and flexibility of digital printing with the durability and boldness of screen printing, offering the best of both worlds. Whether you’re using the Best Digital Printing Machine in…

Even the most advanced digital textile printers can occasionally face print quality issues — from color mismatches and banding to nozzle blockages or misalignment. These small but significant print defects can cause production delays, material waste, and inconsistent results. At Grando, our field technicians have encountered and resolved…

Introduction: Turning Textile Potential into Scalable Success Every successful textile brand starts small — a handful of custom orders, a compact workspace, and a vision to grow. But as demand increases, small setups quickly face the challenges of scaling: inconsistent colors, slower turnaround, machine breakdowns, and rising costs.…

Why Textile Digital Printing Matters The textile industry has undergone a massive transformation in the last decade. Gone are the days when traditional screen printing and block printing dominated fabric production. Today, textile digital printing has become the go-to solution for manufacturers, fashion designers, and businesses who want…