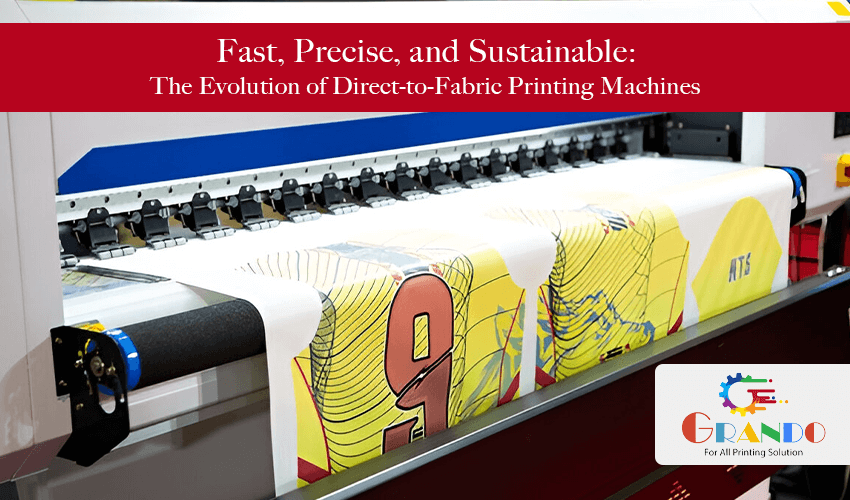

The textile industry has witnessed a massive transformation over the years, with innovation driving efficiency and sustainability. One of the most groundbreaking advancements in textile printing is the rise of direct to fabric printing machine. These machines are revolutionizing the way designs are transferred onto fabrics, offering unmatched speed, precision, and eco-friendliness. As the demand for high-quality prints and sustainable production grows, businesses must adapt to this technological shift. Let’s explore how Direct-to-Fabric Printing Machines are shaping the future of textile printing.

The Speed Revolution in Textile Printing

Traditional printing methods, such as screen printing, are time-consuming and require extensive setup. In contrast, Direct to Fabric Printing Machine eliminate the need for screens and plates, enabling a faster turnaround time. With advanced inkjet technology, these machines can print complex designs in minutes, significantly reducing production time. Brands and manufacturers can now meet consumer demands with greater efficiency, ensuring faster delivery cycles without compromising on quality.

Precision at Its Best

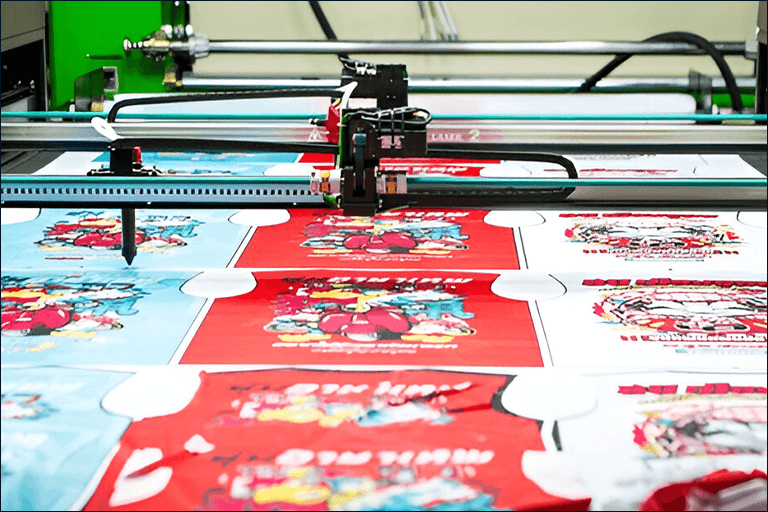

Precision is crucial in textile printing, and Direct-to-Fabric Printing Machines have set a new benchmark in accuracy. Unlike conventional methods that may cause misalignment or inconsistencies, direct-to-fabric technology ensures every detail is printed with impeccable sharpness. This is especially beneficial for intricate designs, gradients, and fine patterns. Businesses in the fashion and home décor industries can now offer high-definition prints that were previously difficult to achieve with traditional techniques.

Sustainability: A Game-Changer

With the global focus shifting towards eco-friendly solutions, Direct-to-Fabric Printing Machines are leading the way in sustainable textile printing. Here’s how they contribute to a greener planet:

- Minimal Water Usage: Unlike dyeing processes that require massive amounts of water, direct-to-fabric printing uses minimal water, reducing waste and pollution.

- Eco-Friendly Inks: Many of these machines use water-based inks that are free from harmful chemicals, making them safe for the environment and consumers.

- Lower Energy Consumption: Digital printing requires less energy compared to traditional methods, leading to a lower carbon footprint.

- Reduced Fabric Waste: With precise printing capabilities, these machines ensure less fabric wastage, optimizing material usage.

By adopting Direct to Fabric Digital Printer in Surat, businesses can significantly cut down on environmental impact while maintaining profitability.

The Future of Textile Printing with Direct-to-Fabric Technology

The demand for customized and sustainable fashion is at an all-time high. Consumers want unique designs, quick turnaround times, and eco-conscious products. Direct-to-Fabric Printing Machines align perfectly with these evolving needs. The future holds even greater possibilities with advancements in AI-driven printing, automation, and improved ink formulations.

Businesses that invest in this technology will gain a competitive edge, reducing operational costs while meeting the high expectations of modern consumers. Whether it’s fashion, home textiles, or industrial applications, Direct-to-Fabric Printing Machines are paving the way for a more efficient and sustainable textile industry.

Choose Grando India for the Best Direct-to-Fabric Printing Machines

If you’re looking for cutting-edge Direct-to-Fabric Printing Machines, Grando India offers state-of-the-art solutions tailored for your business. With high-speed performance, precision printing, and eco-friendly features, our machines help you scale your production while embracing sustainability.

Upgrade your textile printing process today with Grando India and stay ahead in the competitive market.

Contact us now to explore the best printing solutions for your business!