Choosing a Textile Digital Printing Machine for commercial fabric printing is not just a technical decision—it’s a business decision. The wrong machine can slow production, waste ink, and frustrate customers. The right one? It becomes the backbone of a profitable printing operation.

With the growing demand for customized fabrics, short-run production, and fast turnaround, textile businesses—especially hubs like Surat—are rapidly shifting toward digital solutions. But not all machines are built for real-world commercial use.

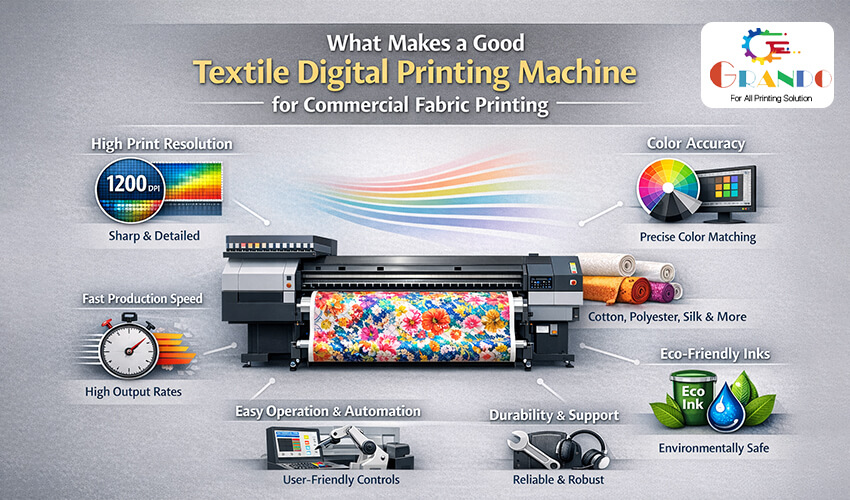

1. Print Quality That Sells the Fabric

In commercial fabric printing, quality is non-negotiable. Customers notice uneven color, banding, or dull prints immediately.

A good textile fabric printing machine should deliver:

- Sharp details on fine patterns

- Consistent color across long print runs

- Smooth gradients without visible lines

High-resolution output (typically 1200 dpi or above) ensures designs look premium, whether you’re printing sarees, dress materials, upholstery, or home textiles.

2. Speed That Matches Commercial Demand

Speed isn’t about bragging rights—it’s about meeting deadlines.

A commercial-grade textile digital printing machine must handle:

- Bulk orders without overheating

- Continuous operation across shifts

- Stable speed without quality drop

For businesses in Surat that use digital printing machines, where competition is intense and delivery timelines are tight, slow machines are silent profit killers.

Look for machines that balance speed with consistency. Fast but unreliable is worse than slow.

3. Fabric and Ink Compatibility

A good Textile Digital Printing Machine should work across multiple fabric types:

- Cotton

- Polyester

- Silk

- Blended fabrics

Equally important is ink compatibility. Reactive, disperse, pigment, or acid inks should be supported based on your target market.

Many commercial printers prefer pigment inks because they reduce post-processing steps and water usage—saving time and operating costs.

Flexibility here means you can accept more types of orders without saying “no” to customers.

4. Reliable Print Heads and Easy Maintenance

Print heads are the heart of any Digital Textile Printer in Surat or anywhere else.

What to look for:

- Industrial-grade print heads from trusted brands

- Easy access for cleaning

- Stable ink flow to reduce clogging

Downtime costs money. A machine that’s easy to maintain keeps production running and stress levels low. If basic servicing requires a technician every time, that’s a red flag.

5. Color Management and Software Control

Commercial printing lives and dies by color accuracy.

A strong textile digital printing machine should include:

- Advanced RIP software

- Color profiling tools

- Repeatable color output across batches

This matters especially for repeat clients who expect the same shade every time. If today’s red becomes tomorrow’s orange, you’ll hear about it—loudly.

Good software also reduces waste, improves layout efficiency, and speeds up job setup.

6. Durability for Long-Term Use

Commercial fabric printing is not gentle work. Machines run daily, often for long hours.

A good Textile Digital Printing Machine should offer:

- Heavy-duty frame construction

- Stable fabric feeding system

- Long operational life

This is where cheaper machines usually fail. They work fine during demos, then struggle under real production pressure.

If you’re serious about scaling, durability isn’t optional.

7. Energy and Ink Efficiency

Margins matter. A lot.

Modern textile businesses look for machines that:

- Consume less power

- Optimize ink usage

- Reduce fabric waste

Lower cost per meter gives you pricing power, especially in competitive markets like Surat. Over time, this efficiency is exactly what defines the Best Digital Printing Solutions in India reputation.

8. Local Support and Service Availability

Even the best machines need support.

If you’re investing in a digital printing machine in Surat, local service availability is crucial. Fast response times, spare parts access, and trained technicians can mean the difference between a small hiccup and a production shutdown.

Always ask:

- How fast is service response?

- Are spare parts locally available?

- Is training included?

Support isn’t an extra—it’s part of the machine.

9. Scalability for Business Growth

A smart investment looks ahead.

A good textile digital printing machine should support:

- Higher production volumes as demand grows

- New fabric types or inks in the future

- Integration with finishing equipment

Buying only for today’s needs often leads to replacement sooner than expected. Think two to three years ahead, not two months.

Why Textile Businesses in Surat Prefer Digital Printing

Surat is a textile powerhouse, and digital printing fits perfectly with its fast-moving market.

A Digital Textile Printer in Surat allows businesses to:

- Offer customization

- Reduce inventory risk

- Respond quickly to fashion trends

That’s why digital printing is no longer an option—it’s a competitive necessity.

Final Thoughts

A good Textile Digital Printing Machine is not defined by specs alone. It’s defined by how well it performs on the shop floor, day after day.

When choosing a machine, focus on:

- Print quality

- Speed and reliability

- Fabric flexibility

- Maintenance ease

- Long-term cost efficiency

Ready to Upgrade Your Textile Printing Business?

If you’re looking for a reliable textile digital printing machine or a trusted digital printing machine in Surat, now is the time to invest smart.

Contact us today to get expert guidance, competitive pricing, and the right solution for your fabric printing needs.

Because in commercial printing, the right machine doesn’t just print fabric—it prints growth.