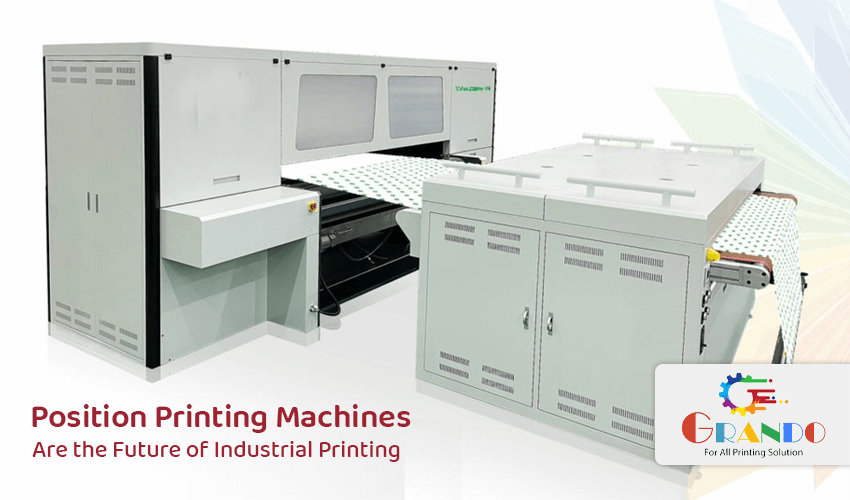

In the ever-evolving landscape of industrial printing, technological advancements are key to staying competitive. Among these innovations, printing machines are making waves as a transformative force in the industry. With their unparalleled precision and efficiency, these machines are setting new standards for quality and productivity. As industries in Surat and beyond seek to enhance their printing capabilities, understanding the benefits of position printing machines becomes crucial.

In this blog, we’ll explore why position printing machines are poised to be the future of industrial printing and how investing in this technology can propel your business forward.

The Rise of Position Printing Machines

These printing machines are engineered to offer exceptional accuracy and consistency, which are critical for high-quality printing applications. Unlike traditional printing methods that may struggle with alignment and positioning, these machines leverage advanced technology to ensure precise placement of prints, reducing errors and improving overall output quality.

This advancement is particularly relevant in Surat, a city known for its vibrant industrial sector. As businesses in Surat and across the globe aim to meet rising demands for high-quality, detailed prints, position printing machines offer a solution that enhances both performance and efficiency.

1. Unmatched Precision and Accuracy

At the core of the appeal of position printing machines is their ability to deliver unmatched precision and accuracy. These machines are designed to handle complex and intricate designs with exacting detail, ensuring that prints are aligned perfectly and colors are reproduced accurately.

This level of precision is essential for industries that require fine details and consistent quality, such as electronics, packaging, and textiles. The advanced positioning technology in these machines minimizes misalignment and print defects, resulting in a flawless final product.

2. Enhanced Efficiency and Productivity

Efficiency is a key factor in maintaining a competitive edge in industrial printing. Position printing machines are engineered to maximize productivity by streamlining the printing process. With features such as automated alignment and high-speed printing capabilities, these machines reduce the time required for setup and production.

Automation speeds up printing, cuts manual work, lowers labor costs, and reduces errors. This efficiency is particularly beneficial for businesses handling large volumes of print jobs, allowing them to meet tight deadlines and increase overall throughput.

3. Versatility Across Applications

One of the standout features of position printing machines is their versatility. These machines are capable of handling a wide range of printing applications, from intricate designs on small components to large-scale prints on various substrates.

Whether you work with textiles, packaging materials, or industrial components, you can adapt position printing machines to meet different requirements. This versatility makes them an invaluable asset for businesses looking to diversify their product offerings and expand their market reach.

4. Cost-Effectiveness and Waste Reduction

Investing in position printing machines can lead to significant cost savings over time. Traditional printing methods often involve high setup costs and material waste, particularly when dealing with complex or multi-color designs. These machines deliver precise control of ink application and alignment, reducing waste and cutting production costs.

By minimizing material wastage and improving print accuracy, businesses can achieve better ROI and contribute to more sustainable manufacturing practices. This cost-effectiveness is a major advantage for companies looking to enhance their profitability while maintaining high standards of quality.

5. Advanced Technology Integration

The future of industrial printing lies in the integration of advanced technologies, and position printing machines are at the forefront of this trend. These machines incorporate state-of-the-art features such as digital controls, real-time monitoring, and automated adjustments, ensuring optimal performance and reliability.

Businesses in Surat gain an edge by investing in advanced position printing machines, boosting speed and quality in a fast-changing market. The integration of these advanced technologies not only improves print quality but also streamlines operations and enhances overall efficiency.

6. Grando India: Leading the Way in Position Printing Technology

When it comes to adopting position printing machines, choosing a reliable supplier is essential. Grando India is a leading name in the industry, offering high-quality Digital printing machines in Surat that are designed to meet the diverse needs of modern industrial printing.

Grando India’s machines are precise, durable, and easy to use. The company drives innovation and supports businesses with excellent service, helping them fully benefit from advanced printing technology.

Conclusion of Position Printing Machines

The emergence of position printing machines marks a significant shift in industrial printing technology. These machines deliver precision, efficiency, and versatility, and they define the future of printing. By investing in position printing technology, businesses can enhance their production capabilities, reduce costs, and stay ahead of the competition.

Ready to elevate your industrial printing with the latest technology? Explore the advanced position printing machines in Surat offered by Grando India and discover how our solutions can transform your printing operations. Contact us today for more information and to find the perfect machine for your business needs!