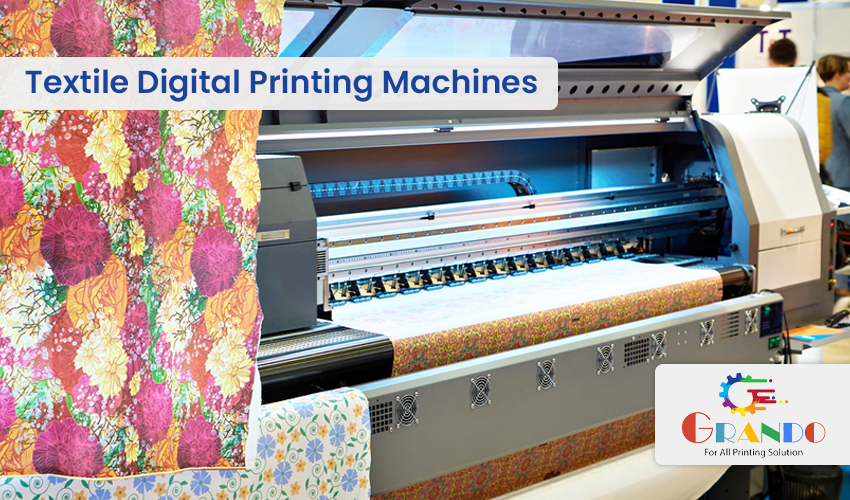

The dynamic world of textile manufacturing, digital printing machines have become game-changers. These innovative machines have revolutionized the process of designing, printing, and producing fabrics. This article delves into the world of textile digital printing machines, exploring their technology, benefits, applications, and future trends.

Understanding Digital Printing Machines for Textiles

What is a Textile Digital Printing Machine?

A digital printing machine for textiles utilizes digital technology to transfer designs directly onto fabric. This method is in contrast to traditional techniques like screen printing, which require multiple steps and are often less flexible. Digital printing machines offer precision, speed, and a broad range of design possibilities.

How Does a Digital Printing Machine Work?

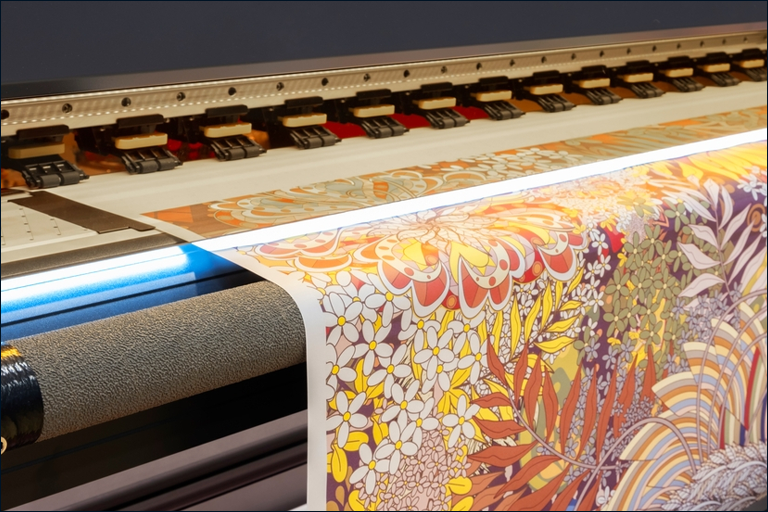

Digital printing machines operate by using inkjet technology to apply ink directly onto the fabric. This method allows for precise color application and intricate design details that traditional methods often can’t achieve.

Benefits of Textile Digital Printing Machines

- Versatility: Digital printing machines can print on a wide variety of fabrics including cotton, polyester, silk, and blends. This versatility is unmatched by traditional printing methods, making it possible to create intricate designs with fine details.

- Cost-Effectiveness: Traditional printing methods involve significant setup costs and are not viable for small batches. In contrast, digital printing machines are cost-effective for both small and large-scale productions. This makes them ideal for on-demand printing and niche markets.

- Customization: One of the standout features of textile digital printer machines is the ability to produce customized prints. This capability is particularly valuable in the fashion industry, where personalized designs are increasingly in demand. Designers can experiment with different patterns, colors, and effects without the constraints of minimum order quantities.

- Eco-friendliness: Compared to traditional printing techniques, digital printing is more environmentally friendly. It generates less waste, consumes fewer resources, and uses water-based inks that are free from harmful chemicals, reducing the environmental impact.

Applications of Textile Digital Printing Machines

The versatility of textile digital printer machines opens up a myriad of applications across various industries:

- Fashion and Apparel: Digital printing has revolutionized the fashion industry by enabling designers to create intricate and vibrant prints with ease. From haute couture garments to everyday wear, digital printing machines are used to produce clothing, accessories, and even footwear with stunning visual effects.

- Home Textiles: Textile digital printer machines are also widely employed in the production of home textiles, including curtains, upholstery, bedding, and towels. The ability to print custom designs allows manufacturers to cater to diverse aesthetic preferences and interior décor trends.

- Sportswear and Activewear: In the sportswear and activewear sector, digital printing offers advantages such as moisture-wicking properties and vibrant colors that withstand rigorous physical activity. This makes it an ideal choice for producing performance-oriented apparel with eye-catching designs.

- Soft Signage: Digital printing machines are increasingly used for soft signage applications like banners, flags, and exhibition graphics. The lightweight and durable nature of digitally printed fabrics makes them convenient for indoor and outdoor advertising, events, and displays.

Key Types of Textile Digital Printer Machines

India is home to several top-notch digital printing machine manufacturers. The best digital printing machines in India are known for their reliability, advanced features, and cost-effectiveness, making them popular choices in both domestic and international markets.

Direct to Fabric Printing Machine

Direct to fabric printing machines, also known as direct-to-garment (DTG) printers, apply designs directly onto the fabric without the need for transfer paper. This method is efficient, reduces material waste, and ensures high-quality prints.

Best Digital Printing Machine in India

India is home to several top-notch digital printing machine manufacturers. The best digital printing machines in India are known for their reliability, advanced features, and cost-effectiveness, making them popular choices in both domestic and international markets.

ColorJet Digital Printers

ColorJet offers a range of digital textile printers known for their reliability and high-quality output. Their machines are designed to handle various fabrics and deliver vibrant prints.

Position Printing Machine

Position printing machines are a subset of digital printers that excel in placing prints precisely on specific areas of the fabric. This capability is essential for complex designs and patterns that require exact alignment.

The Future of Textile Digital Printing

Integration with Advanced Finishing Techniques

Future advancements will likely see digital printing integrated with techniques such as coating, embossing, and laser cutting. This will enhance the tactile and visual properties of printed fabrics, offering even greater design possibilities.

Emphasis on Sustainability

Sustainability will continue to drive innovation in textile digital printing. The development of eco-friendly inks and recycling technologies will further reduce the environmental impact of textile production.

Growth of On-Demand Production

The trend towards on-demand production is set to grow, driven by e-commerce and the demand for personalized products. Digital printing machines are perfectly suited to meet this demand, offering quick turnaround times and cost-effective production.

Challenges and Considerations

While textile digital printer machines offer numerous advantages, there are some challenges to consider:

- Color Matching: Achieving consistent color reproduction across different batches can be challenging and may require careful calibration.

- Fabric Compatibility: Not all fabrics are suitable for digital printing, and pre-treatment may be necessary to ensure optimal print quality and durability.

- Initial Investment: Investing in a textile digital printing machine can be costly, particularly for small businesses or startups.

Conclusion

Textile digital printer machines have transformed the fabric printing landscape, offering unmatched versatility, customization, and sustainability. From fashion to home textiles and signage, digital printing is driving innovation and creativity in the textile industry. As technology continues to advance and consumer preferences evolve, the future of textile digital printing holds exciting possibilities for further growth and development.