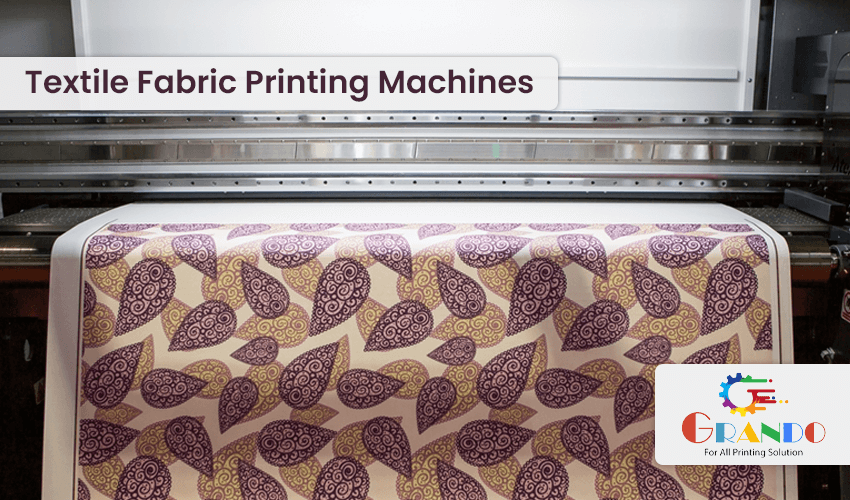

In the dynamic world of textile manufacturing, the advent of fabric printing machines has brought about significant changes, revolutionizing the way fabrics are designed, printed, and produced. These machines, including digital printing machines, position printing machines, and direct-to-fabric printing machines, have had a profound impact on the textile industry, influencing everything from design flexibility to production efficiency. In this article, we explore the transformative effects of textile fabric printing machines and their role in shaping the future of the industry.

Introduction to Textile Fabric Printing Machines

Textile fabric printing machines encompass a range of technologies designed to print digital designs directly onto fabric. From traditional methods like screen printing to advanced digital printing techniques, these machines have evolved to meet the growing demands of the textile industry.

Understanding Digital Printing Machines

Digital printing machines utilize inkjet technology to transfer digital designs onto fabric. They offer unparalleled flexibility, allowing for intricate patterns, vibrant colors, and high levels of customization. Unlike traditional printing methods, digital printing machines eliminate the need for screens or plates, streamlining the printing process and reducing setup time.

Transforming Manufacturing Processes

Automation and Efficiency

Textile fabric printing machines have automated and streamlined manufacturing processes, reducing manual labor and increasing production efficiency. With features such as digital controls and automated ink delivery systems, these machines can print intricate designs with speed and accuracy, minimizing errors and maximizing output.

On-Demand Production

The versatility of textile fabric printing machines allows for on-demand production, eliminating the need for large inventories and reducing waste. Manufacturers can quickly respond to changing market demands and produce customized products in small batches, catering to niche markets and individual preferences.

Expanding Design Possibilities

Versatility in Fabric Selection

Textile fabric printing machines can print on a wide range of fabrics, including cotton, polyester, silk, and blends. This versatility expands design possibilities, allowing designers to experiment with different textures, weights, and finishes to achieve the desired aesthetic and functionality.

Customization and Personalization

Digital printing technology enables unprecedented levels of customization and personalization in fabric design. Designers can create unique patterns, colors, and effects tailored to specific customer preferences, enhancing the appeal and value of the finished product.

Driving Market Trends

- Fast Fashion: The speed and flexibility of textile fabric printing machines have contributed to the rise of fast fashion, where trends change rapidly, and consumers demand new styles at affordable prices. Digital printing allows fashion brands to quickly prototype and produce trendy designs, reducing time-to-market and staying ahead of competitors.

- Sustainable Practices: As sustainability becomes increasingly important in the textile industry, fabric printer machines play a crucial role in promoting eco-friendly practices. Digital printing reduces water consumption, energy usage, and waste generation compared to traditional printing methods, making it a more sustainable option for textile production.

Exploring Specialized Printing Techniques

Position Printing Machines

Position printing machines are specialized printers that enable precise placement of designs on fabric. They are commonly used for applications where accuracy is paramount, such as logo placement or pattern alignment. Position printing machines enhance the quality and consistency of printed fabrics, ensuring uniformity across production batches.

Direct-to-Fabric Printing

Direct-to-fabric printing eliminates the need for transfer paper or intermediate steps, allowing designs to be printed directly onto the fabric. This method produces vibrant, high-quality prints with excellent color retention and durability, making it ideal for a wide range of applications, from apparel to home textiles.

Conclusion

Textile fabric printer have had a profound impact on the industry, transforming manufacturing processes, expanding design possibilities, and driving market trends. From automation and efficiency to customization and sustainability, these machines play a vital role in shaping the future of textile production. As technology continues to advance, fabric printing machines will continue to push the boundaries of innovation, enabling manufacturers to meet the evolving needs and expectations of consumers worldwide.